Energy strategies against climate change

By Jesús Gómez Hernández, Carolina Marugán Cruz, Sergio Sánchez Gónzalez, Daniel Serrano García and Esperanza Batuecas Fernández (Energy Systems Engineering Group (ISE))

Through its research projects, the university significantly contributes to the effort to combat climate change. Research projects arise through different programs and calls for funding promoted by the European Commission or state and regional programs. The main funding programme for research in Europe is the European Union’s Framework Programme for Research and Innovation, known as Horizon 2020 (now Horizon Europe).

At Carlos III University of Madrid (UC3M) there are numerous research groups working on the fight against climate change. In particular, in this post, we will develop some of the research lines carried out in the Energy Systems Engineering Group (ISE).

Waste valorization through energy recovery

Waste management has become a pressing challenge. In this sense, apart from conventional recycling processes, there are thermochemical processes such as gasification and pyrolysis that allow to process waste. They differ mainly in the amount of oxygen used. In the case of pyrolysis, it is a process that takes place in the absence of oxygen, usually in an inert nitrogen atmosphere. On the other hand, gasification takes place with a small supply of oxygen, existing in this case a small partial combustion that supplies the energy necessary to carry out the process. Both processes allow the waste to be transformed into a fuel, which can then be used to generate electricity, heat or as a raw material in the chemical industry. A solid carbonaceous product, a liquid or biofuel fraction, and a gaseous fraction of several permanent gases are produced during pyrolysis. In contrast, gasification creates a fuel gas that is likewise made of many permanent gases. Reusing and recycling waste directly supports the circular economy, lowers greenhouse gas emissions, and other goals outlined in the European Waste Directive.

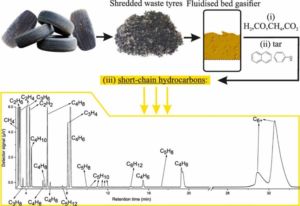

The gasification of waste tires in a bubbling fluidized bed reactor was assessed through the Project financed by the Horizon 2020 BRISK II: Biofuels Research Infrastructure for Sharing Knowledge II. A thorough analysis of the product gas was obtained. The studies were conducted using air as a gasifying agent at temperatures of 700 and 850°C with various equivalence ratios (ER). The impact of adding steam was also investigated at 850 °C. According to the findings, higher temperatures encourage higher outputs of important gas species as H2, CH4, and C2H4. Moreover, the synthesis of H2 increases considerably when steam is added, whereas the CO concentration decreases. Additionally, a large number of light hydrocarbons are produced in quantities that significantly boost the product gas energy potential.

Figure 1. Product gas composition analysis from the waste tires valorization throughgasification in a bubbling fluidized bed reactor.

Solar thermal energy use for industrial heat and electricity production

The goal is to maximize the efficiency of this renewable resource in the production of electricity and in the delivery of heat for industrial operations through the development and optimization of solar thermal energy capture and storage systems. Solar thermal energy, also known as concentrated solar energy, produces heat by concentrating sun radiation using mirrors or lenses. Direct application of this heat in industrial operations is possible, as is thermodynamic cycle-based electricity generation. Utilizing solar thermal energy reduces dependence on fossil fuels and the greenhouse gas emissions.

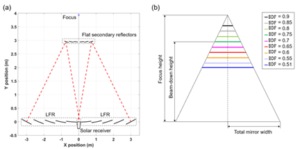

The Beam Down Linear Fresnel Reflector (BDLFR) technology was developed through the projects INTECSOLARIS-CM-UC3M (funded by the Community of Madrid), ACES2030-CM (co-financed by European Structural Funds), or the project Integración de la energía solar en la industria pesada para mitigar las emisiones de CO2 (funded by the State Research Agency).

By using linear and direct concentrated solar energy irradiation, BDLFR technology has been created for the thermal processing of heavy materials at temperatures between 150 and 300 oC. The BDLFR solar field has two levels of reflection as a result. First, a second mirror stage receives sun light from linear Fresnel reflectors. These secondary mirrors are elevated from the ground and use beam-down optics to refocus the concentrated solar energy onto a large, linear receiver that is situated on the ground. The secondary mirrors are flat and placed at the same height, making installation easier while guaranteeing that the sun’s rays are adequately reflected towards the solar receiver’s ground. The heat treatment of heavy materials is made easier by this setup.

Figure 2. Studied configurations of BDLFR solar fields.

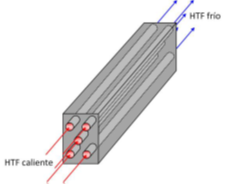

Sustainable energy storage systems in cement.

Conventional cement production is known for its high impact on CO2 emissions and water consumption. Aware of this problem, more sustainable energy storage systems in cement have been developed. Through the incorporation of waste such as slag and the exploration of new materials such as geopolymers, the aim is to develop cements with properties suitable for the storage of thermal energy. These innovations will not only reduce CO2 emissions and water consumption associated with cement production but will also allow new developments to be used as renewable energy storage systems. This approach contributes directly to the decarbonisation of multiple sectors, driving the transition to a low-carbon economy. These developments have been studied thanks to the HORATSO-CM project, funded by the Community of Madrid.

Figure 3. Heat exchange in a concrete block.

Life Cycle Assessment to minimize environmental impacts.

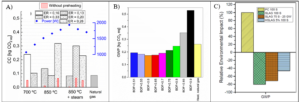

Previous developments were evaluated from the environmental point of view, with the aim of obtaining not only those that are technically better but also environmentally more sustainable. This was conducted by using the Life Cycle Assessment (LCA) methodology. Through the LCA, the environmental impact of a product or process is assessed throughout its entire life cycle, from the extraction of raw materials to its final disposal. The main objective of the LCA is to identify optimal conditions that minimize environmental impacts. By providing accurate and detailed information on the environmental impacts of industrial processes, it contributes towards the implementation of more sustainable strategies.

In the following figure it is possible to see the optimal developments in terms of the Climate Change impact category (also known as carbon footprint or Global Warming Potential, GWP).

- Tire gasification: The combination of high temperature, lower ER and steam addition, offered the most environmentally sustainable process. Despite the great savings in environmental impacts, additional efforts are still needed to reduce the energy consumption of the preheating system to ensure that the product gas is leveled to conventional natural gas.

- BDLFR Prototype: Thermal energy production with different BDLFR configurations performed better than conventional heat from natural gas in all but two configurations. The case study with the lowest carbon footprint represents a 34% reduction compared to natural gas.

- More sustainable cements: It was concluded that thermal storage systems with partial or total replacement of Portland cement with waste (slag) showed >100% reduction in carbon footprint compared to traditional Portland cement.

Figure 4. Carbon footprint results of the above-described technologies. A. Tires gasification. B. BDLFR solar fields. C. Sustainable cements.

These scientific and technological developments are vital to address current environmental challenges and bringing us closer to a world where clean energy and sustainability are a palpable reality. Collaboration between academia, industry and decision-makers is crucial to translate these developments into concrete action to accelerate the transition to a low-carbon economy.